The choices can feel overwhelming when picking materials for your home, especially for something as essential as doors. You want durability, style, and value that stands up to daily life while looking stylish. Plywood is often the go-to material for doors, but not all plywood is created equal. Two standard options, Boiling Water Proof (BWP) plywood and Moisture Resistant (MR) plywood, dominate the conversation. Each has its strengths, but picking the wrong one could mean warped doors, water damage, or a shorter lifespan for your investment.

This article dives into the details of BWP plywood versus MR plywood, breaking down what makes them different. It also breaks down why it matters for doors. Whether you’re a homeowner renovating your space or a builder aiming for quality, understanding these materials will help you make a wise choice. We’ll explore their features, ideal uses, and how they impact the doors you rely on daily. By the end, you’ll know exactly which plywood fits your needs—and why Splice Ply doors might be the perfect solution.

BWP plywood, also known as marine-grade plywood, is designed to resist water pressure. It’s made with a high-quality hardwood veneer bonded together using phenol-formaldehyde resin, a glue that doesn’t budge even when soaked. This makes BWP plywood the heavyweight victor in environments where moisture is constantly threatened. Think bathrooms, kitchens, or homes in humid coastal areas. It’s not all about water resistance—BWP plywood is built to last, resisting warping, cracking, and delamination under harsh conditions.

Here’s what makes BWP plywood stand out:

Complete waterproofing: It can handle prolonged water exposure, even boiling water, for 72 hours without breaking down.

Superior strength: The hardwood layers and strong adhesive give it exceptional durability.

Termite resistance: Often treated with chemicals to repel pests, adding years to its life.

Versatility: It is Perfect for indoor and outdoor use, from kitchen cabinets to exterior doors.

Certified quality: Look for the IS:710 standard in India, ensuring top-tier performance.

BWP plywood isn’t even rugged—it’s a premium choice for projects where failure isn’t an option. Its ability to withstand extreme conditions makes it a favorite for doors that need to endure heavy use or unpredictable weather.

MR plywood, or Moisture Resistant Plywood, is the less expensive cousin of BWP. It’s designed for indoor use where humidity might be a factor, but direct water exposure isn’t a daily concern. Made with urea-formaldehyde resin, MR plywood can handle damp air or occasional splashes but falls short when faced with serious moisture. It’s commonly used for furniture like wardrobes, shelves, or interior doors in low-risk areas.

Moderate moisture resistance: It is suitable for humid environments but not waterproof.

Affordability: Generally cheaper than BWP, appealing to tighter budgets.

Solid strength: It offers decent durability for indoor applications.

MR plywood is a practical choice for living rooms or bedrooms where water isn’t a significant issue. However, it’s not built for the long haul in wet conditions, which can lead to swelling or delamination over time.

Choosing between BWP plywood and MR plywood comes down to your specific needs. Let’s break it down by comparing their performance on key factors:

Water resistance: BWP plywood is fully waterproof and ideal for bathrooms, kitchens, or outdoor areas. MR plywood can handle humidity but degrades with direct water exposure.

Durability: BWP’s hardwood and robust adhesive make it tougher and longer-lasting. MR plywood is durable indoors but weak overall.

Cost: MR plywood is typically 30-40% cheaper than BWP, appealing to budget-constrained projects.

Applications: BWP shines in high-moisture zones and heavy-duty use, while MR suits dry, controlled environments.

Maintenance: BWP requires minimal upkeep due to its resistance to water and pests. MR plywood may need more care in humid conditions.

Weight: BWP is heavier, reflecting its dense construction. MR is lighter and easier to handle on smaller projects.

Sustainable: Both can be sustainable if sourced from certified suppliers, but BWP often uses high-quality, responsibly harvested wood.

This comparison shows BWP plywood as the premium option for demanding environments, while MR plywood offers value for less intense settings.

Doors aren’t limited to being functional—they’re a statement. They face constant handling, temperature swings, and, in some cases, moisture. BWP plywood is uniquely suited to doors because it tackles these challenges head-on. Its waterproof nature ensures your doors won’t warp or swell, even in a steamy bathroom or rain-prone entryway. The strength of BWP plywood also means your doors can handle years of slams, bumps, and everyday damage without losing shape or finish.

Consider these reasons for choosing BWP plywood for doors:

Longevity: BWP doors last decades, resisting water, pests, and physical stress.

Aesthetic flexibility: Available in various finishes, it supports custom designs that elevate your home.

Low maintenance: A quick wipe-down will keep them looking new, no matter the condition.

For exterior doors or homes in humid climates, BWP plywood is practically non-negotiable. The material gives you peace of mind, knowing your doors will stand firm.

MR plywood has its merits, mainly if your project doesn’t involve water-heavy areas. For interior doors in bedrooms, living rooms, or offices, MR plywood is a wise choice. It’s strong enough for standard use and reduces costs, letting you allocate your budget to other design elements like paint or hardware. However, you must ensure the environment stays dry to avoid long-term issues.

Here’s when MR plywood makes sense:

Budget projects: When you need quality without breaking the bank.

Dry interiors: Perfect for controlled humidity spaces, like closets or study rooms.

Temporary solutions: If you’re staging a home or building short-term structures.

Lightweight needs: Easy to work with for smaller, less demanding doors.

Quick installations: Its availability and lower cost speed up projects.

MR plywood is a solid choice for low-risk areas but not a substitute for BWP in high-moisture zones.

At Splice Ply, we know doors are larger than just entryways—they’re the backbone of your home’s style and security. That’s why we use premium BWP plywood in our doors, ensuring they withstand moisture, damage, and time. Our doors combine strength with stunning design, offering everything from sleek modern looks to timeless classics. Whether you need an exterior door to brave the elements or a bathroom door to handle steam, Splice Ply delivers exceptional quality. Contact us at Contact Us to explore our range and see how our BWP plywood doors can elevate your space. Let’s build something lasting together.

What is calibrated plywood

What is calibrated plywood

BWP Plywood vs MR Plywood Which to Choose

BWP Plywood vs MR Plywood Which to Choose

Best Quality Plywood Sheets in India

Best Quality Plywood Sheets in India

The Making of a Membrane Door

The Making of a Membrane Door

High Gloss Laminate Sheets for Modern Doors

High Gloss Laminate Sheets for Modern Doors

Top Reasons to Choose the Perfect Door Laminate Design Ideas for Your Home

Top Reasons to Choose the Perfect Door Laminate Design Ideas for Your Home

Pros and Cons of laminate doors

Pros and Cons of laminate doors

Laminate Door Design for Modern Spaces

Laminate Door Design for Modern Spaces

What is Flush Doors

What is Flush Doors

The Complete Breakdown of Plywood Types in India for Every Interior Need

The Complete Breakdown of Plywood Types in India for Every Interior Need

Everything You Need to Know About Laminate Sheets and Their Applications

Everything You Need to Know About Laminate Sheets and Their Applications

Modern and Stunning: TV Panel Wall Designs You Can Achieve with Laminates

Modern and Stunning: TV Panel Wall Designs You Can Achieve with Laminates

15 Unique Wardrobe Designs for Your Bedroom

15 Unique Wardrobe Designs for Your Bedroom

Main Door Design Ideas for Classic Homes

Main Door Design Ideas for Classic Homes

Laminate Brands in India

Laminate Brands in India

Unlocking Profitable Partnerships Joining the Splice Flush Door Revolution

Unlocking Profitable Partnerships Joining the Splice Flush Door Revolution

Elevate Your Interior Design with Rock Retail Splice Flush Doors

Elevate Your Interior Design with Rock Retail Splice Flush Doors

Benefits of calibrated plywood and it’s uses

Benefits of calibrated plywood and it’s uses

Splice 16mm Calibrated Plywood

Splice 16mm Calibrated Plywood

Splice Makes a Mark With the Launch of Its Exterior Claddings

Splice Makes a Mark With the Launch of Its Exterior Claddings

What Is Calibrated Plywood? What Are Its Benefits and Uses

What Is Calibrated Plywood? What Are Its Benefits and Uses

Top 10 Plywood Brands in India

Top 10 Plywood Brands in India

Top 10 Benefits of Installing Flush Doors in Your Home

Top 10 Benefits of Installing Flush Doors in Your Home

Choosing the Right Laminate for Your Door: Factors to Consider

Choosing the Right Laminate for Your Door: Factors to Consider

Fire-Resistant vs. Standard Doors: What's the Difference and Why It Matters

Fire-Resistant vs. Standard Doors: What's the Difference and Why It Matters

Choosing the right laminate for your home style durability and maintenance

Choosing the right laminate for your home style durability and maintenance

Transform your space with these creative ways to use laminates

Transform your space with these creative ways to use laminates

Innovative Uses of Laminates in Bathroom Daccor - A Stylish and Waterproof Solution

Innovative Uses of Laminates in Bathroom Daccor - A Stylish and Waterproof Solution

Fire Retardant Door

Fire Retardant Door

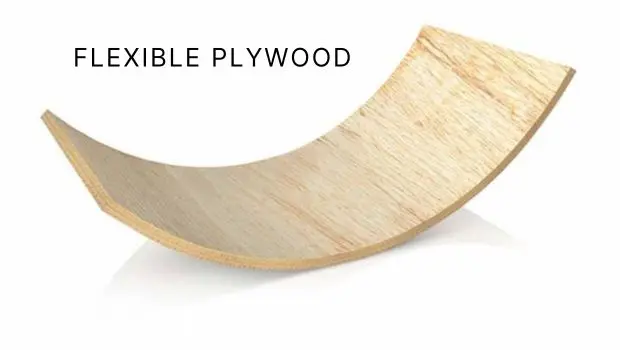

What is Flexible Plywood

What is Flexible Plywood

Know About Splice Marine Grade Plywood

Know About Splice Marine Grade Plywood